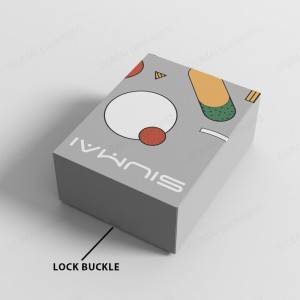

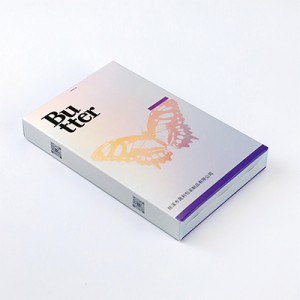

Regular folding boxes with lock buckle

| Box Style | Regular folding boxes with lock buckle |

| Dimension (L + W + H) | All Custom Sizes Available |

| Quantities | No MOQ |

| Paper choice | White cardboard, Karft paper, [ABCDEF] Flute Corrugated, Hard grey board, Laser paper etc. |

| Printing | CMYK Colors,Spot color printing [All use environmentally friendly UV inks] |

| Finishing | Gloss Lamination, Matte Lamination, Matt varnishing, Glossy varnishing, Spot UV, Embossing, Foiling |

| Included Options | Desgin, Typesetting, Coloring match, Die Cutting, Window Sticking, Glued, QC, packaging, Shipping, Delivery |

| Additional Options | Embossing, Window Patching, [Gold/silver] Foil Hot Stamping |

| Proof | Die line, Flat View, 3D Mock-up |

| Delivery time | When we receive the deposit, it takes 7-12 business days for producing the boxes. We will reasonably arrange and plan the productioncycle according to the quantity and material of the boxes to ensure on-time delivery. |

| Shipping | Shipping transports, Train transports, UPS, Fedex, DHL, TNT |

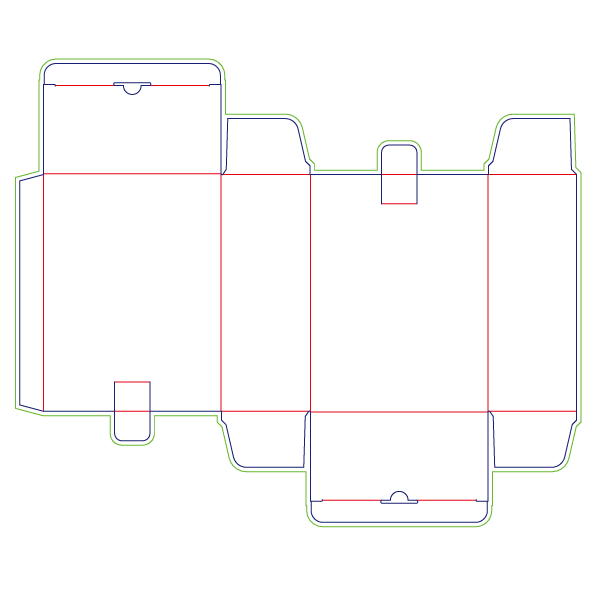

BLEED LINE [GREEN] ━━━

Bleed line is one of the specialized terms for printing. Inside the bleed line belongs to the printing range, and outside the bleed line belongs to the non-printing range. The function of the bleed line is to mark the safe range, so that the wrong content will not be cut during die cutting, resulting in blank space. The value of the bleed line is generally 3mm.

DIE LINE [BLUE] ━━━

Die line refers to the direct die-cutting line, that is the finished line. The blade is pressed directly through the paper.

CREASE LINE [RED] ━━━

Crease line refers to the use of steel wire, through embossing, to press marks on the paper or leave grooves for bending. It can facilitate the folding and forming of subsequent cartons.

White Cardboard

Black Cardboard

Corruated Paper

Specialty Paper

Kraft Cardboard

Kraft Cardboard

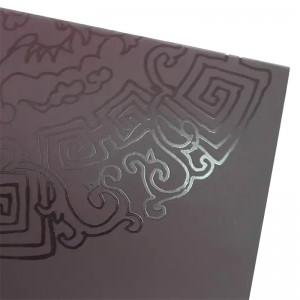

Spot UV

Pro-Cure UV

Sliver Foil

Gold Foil

Embossing

Debossing

Matte Lamination

Glossy Lamination

01) Design concept

This is great if you have your own design. We only need to determine the styles and specific materials of the box according to the weight, material, shipping method, etc. of the product. to ensure your products are packaged in the most beautiful way possible. If you have no specific design ideas. Please don't worry, tell us your specific product content and intended design pattern, we have the most professional packaging designers to help you design the best packaging and create the most special packaging for your brand.

02) Choose your order

If you have a specific order, please send us a list of products that may be suitable for your project. Make sure to mark the custom size and material of your favorite product and send it to us via SNS such as email. We will reply to you as soon as possible to start your packaging journey.

03) Get a quote

When we have confirmed the quote request for all all product specifications, our product specialists will begin preparing your quote. A simple quote will be sent to you within 24 hours. For projects with special structures and materials, it may take more than 24 hours, but we will also reply to you within 72 hours. Your dedicated product specialist will be in touch to keep you connected throughout the shopping process to ensure your order is responded to in a timely manner.

04) Prepare the order

Once you have received a quote from our product experts, please check it to ensure all your quote details are correct. If you have any additional questions about your product, please always contact your product specialist for more information. If you are satisfied with your offer and can proceed, please make a deposit payment through the secure payment account provided to you by our product experts.

05) Get your custom cutting lines and print files

Our designers will have your files ready within 1 to 2 business days before your order is ready to start. It includes your custom print and cut files, and we'll generate a 3D box rendering for you. This allows you to preview your packaging details before production to ensure smooth production of your boxes.

06) Start production

Once you have approved everything, your packaging production begins! During this phase, our experts are in constant contact with you to ensure you have the latest production progress! At the same time, our QC will also conduct random sample inspection during production to ensure that there will be no errors.