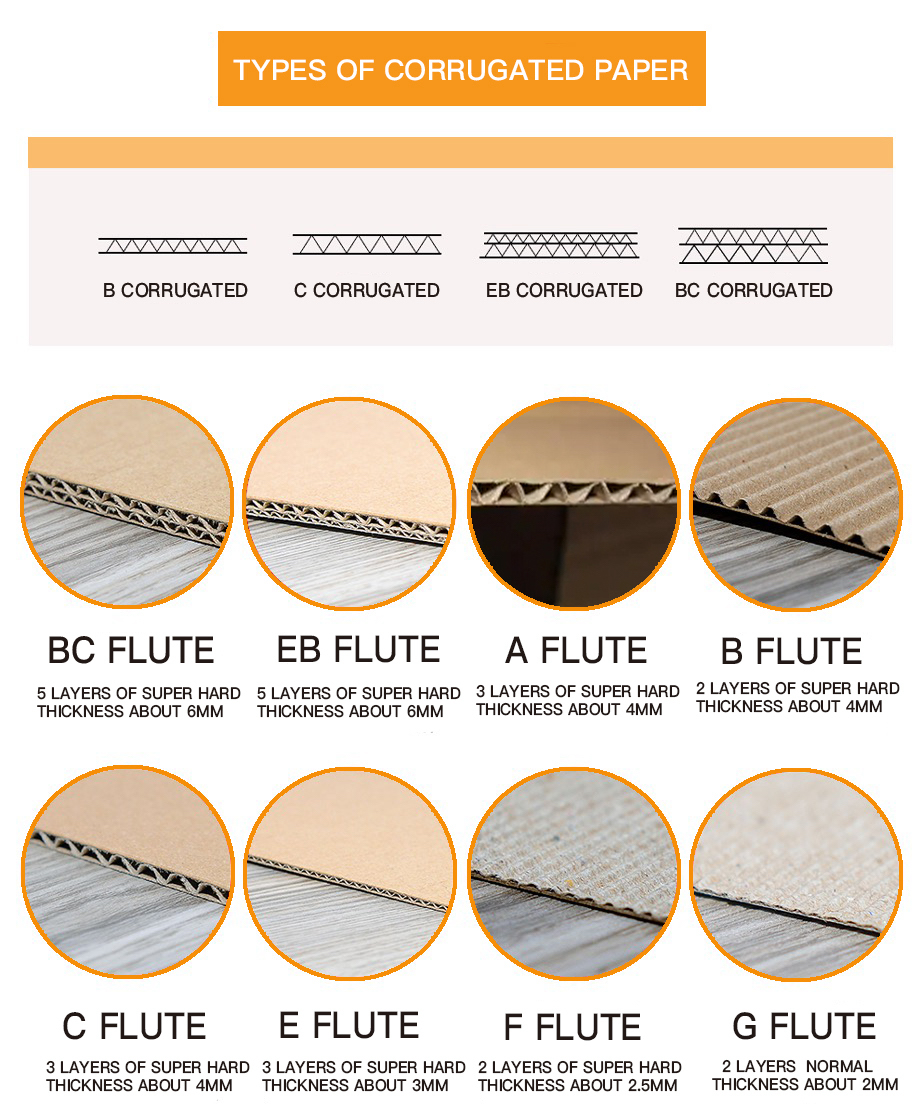

The typical structure of corrugated cardboard is a clever combination of face paper and corrugated paper. From the perspective of structural mechanics, its shape flute is very scientific and reasonable.

The corrugated type of corrugated cardboard,

The core part of corrugated cardboard is corrugated, so the shape, flute and combination of corrugated have a great influence on the characteristics of corrugated paper. Let’s talk about the basic points of corrugated type.

Now, the corrugated type is roughly divided into: a-flute corrugated, b-flute corrugated, c-flute corrugated, of which micro corrugated (from high to short according to corrugated height) are e-flute corrugated, f-flute corrugated, g-flute corrugated, n-flute corrugated, o-flute corrugated.

1) A-flute corrugated

The characteristic of a-type corrugation is that the number of corrugations per unit length is small, and the corrugation is the highest. Corrugated boxes made of A-flute flutes are suitable for packaging lighter items and have greater buffering force. A-flute corrugated cardboard has the largest corrugation height and spacing, is soft and has good elasticity, so that it has good cushioning performance and large bearing capacity. , as well as bushings, pads and shock absorbers for products with high requirements for shock, collision and various loads.

2) b-flute corrugated

The b-type flute is just the opposite of the a-flute. The number of corrugations per unit length is large and the corrugation is the lowest. Its performance is also the opposite of the a-type flute. The corrugated box made of the b-type flute is suitable for packing heavier and harder items. B-type corrugated cardboard has a small corrugated spacing, more corrugated strips per unit length, and more support points with the surface layer and the bottom layer, and has a high flat pressure strength, so it is not easily deformed under pressure and has good stability. ; The corrugated cardboard has a relatively flat surface and high rigidity, and can obtain better printing effects during printing; and is easy to cut. B-flute corrugated cardboard is usually used to make the packaging of products that have sufficient rigidity and do not require shock absorption protection, such as packaging of cans, daily chemical products, small packaged foods, hardware, and woodwareh. B-flute corrugated cardboard with double-layer structure can also usually be used to package items that require surface protection, such as valuable furniture, pictures, lamps, etc.

3) c-flute corrugated

The number of corrugations per unit length and the corrugated height of the c-type corrugated are between the a-type corrugated and the b-flute corrugated. The performance is close to the A-type flute. In recent years, with the increase of storage and transportation costs, the smaller c-shaped flute has been paid attention to, and it has become the flute type adopted by European and American countries. C-flute corrugated cardboard combines the characteristics of A-type corrugated cardboard and B-flute corrugated cardboard, and has certain rigidity and good shock absorption performance. Therefore, it can be effectively used to package fragile (glass, ceramic, etc.) products as well as hard products that require protection of their surfaces.

4) e-flute corrugated

The number of e-shaped flutes in the length of 30 cm is generally about 95, which is thinner and harder. Therefore, the main purpose of developing e-flute is to make it into a folding carton to increase cushioning, usually used for decorative corrugated boxes. D-flute corrugated cardboard and E-flute corrugated cardboard have more corrugations per unit length, and the surface and plane stiffness of the flat suit can be obtained. In this way, high-quality sales packaging and decoration printing can be carried out on its surface, which plays a good role in visual performance.

Post time: May-09-2022