China wholesale Eyelash Packaging Box Wholesale Manufacturer – Soap Kraft Paper Box Printing Soap Paper Packaging Custom Design – SIUMAI packaging

China wholesale Eyelash Packaging Box Wholesale Manufacturer – Soap Kraft Paper Box Printing Soap Paper Packaging Custom Design – SIUMAI packaging Detail:

| Style | All materials and box types can be customized |

| Size | All Custom Sizes Available |

| MOQ | Normally 5000 pcs, Please email for specific quantity |

| Printing | CMYK Colors, Pantone spot color |

| Included Options | Die Cutting, Gluing, Perforation, Magnet, ribbon, EVA, plastic tray, sponge, PVC/PET/PP window, Die Cutting, Gluing, Perforation ,etc. |

| Finishing | Lamination, varnishing, gold/silver foil, hot stamping, embossing, debossing, UV / Customized |

| Quotation | Within 24 hours after confirming the material, size, quantity, printed content and details |

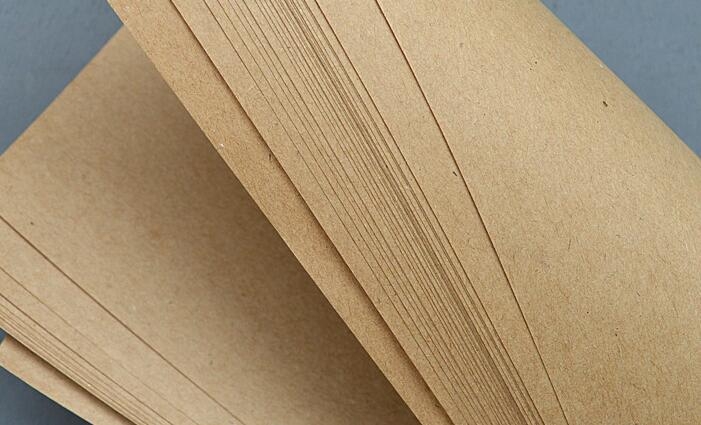

With the improvement of living standards, the awareness of environmental protection has been deeply rooted in the hearts of the people. Many products have been packaged with environmentally friendly materials. Of course, kraft paper is naturally one of them! Because the brown of kraft paper itself looks to give people a warm nostalgia, it is quite popular. The performance of food-grade kraft paper is very superior, not only has the advantages of moisture-proof, waterproof, oil-proof, low-temperature freezing resistance, and delayed insurance period.

Compared with packaging materials such as plastic and glass, its cost is ten to twenty percent lower under the same barrier effect. Food-grade kraft paper is usually made of pure wood pulp, which is much stronger than plastic packaging in terms of hygiene and safety, and kraft paper packaging can be recycled and reused, which is better than plastic packaging in terms of environmental protection.

In addition, even if the kraft paper packaging is piled up on the ground, it will quickly be degraded in the soil. Unlike plastic packaging, which is difficult and easy to degrade, it causes “white pollution” and has a destructive effect on the soil and the environment.

The classification of kraft paper packaging, from the materials used in kraft paper packaging, kraft paper packaging can be divided into packaging kraft paper and cattle cardboard.

1. General kraft paper for packaging is collectively referred to as kraft paper packaging. The performance of kraft paper packaging mainly includes: high strength, low cost, good air permeability, and abrasion resistance. Common kraft paper packaging includes shopping bags, document bags, etc.

2. Kraft paper with a higher number of grams has a smooth surface, clothing tags, archive boxes, portfolios, etc. At the same time, it is supported by natural raw materials, and non-toxic kraft paper is mostly used for food packaging.

3. The raw materials for cardboard manufacturing are basically the same as kraft paper. We call it cow cardboard. The difference from kraft paper is hardness, thickness, rigidity, and easy processing. It is the main paper used to make cartons.

When a product is packaged with kraft paper, since kraft paper is made of wood fiber, the packaging made with it can be completely recycled and reused many times. These are unmatched by other packaging materials.

These can be seen from the wide application of kraft paper packaging. The new kraft paper packaging will be more and more recognized and valued by designers;

Kraft paper is a tough, water-resistant packaging paper with a brownish-yellow color, and it has a wide range of uses. It is widely used in paper boxes, cartons, handbags, color boxes, gift boxes, wine boxes, document bags, clothing tags and other fields. It not only has strong physical properties.

Compared with ordinary paper, it is much higher than ordinary paper in terms of toughness, tensile strength, burst resistance, stiffness, and printing effect. Not only is the color favored by the public. It also has excellent moisture-proof performance. For tea collectors, its strong moisture-proof ability can prevent the tea from being damp and moldy.

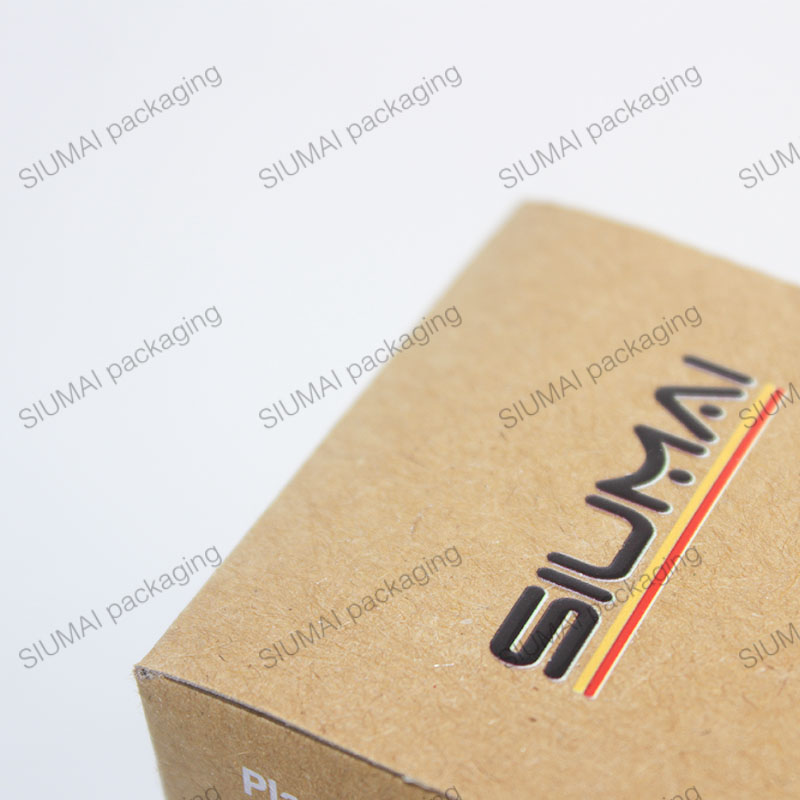

Product detail pictures:

Related Product Guide:

Our improvement depends on the superior equipment, excellent talents and continuously strengthened technology forces for China wholesale Eyelash Packaging Box Wholesale Manufacturer – Soap Kraft Paper Box Printing Soap Paper Packaging Custom Design – SIUMAI packaging , The product will supply to all over the world, such as: Russia, Swiss, Plymouth, Although continuous opportunity, we have now developed serious a friendly relationship with many oversea merchants, such as ones through Virginia. We securely assume that the merchandise regarding t shirt printer machine is often good through a great number of having its good quality and also cost.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.