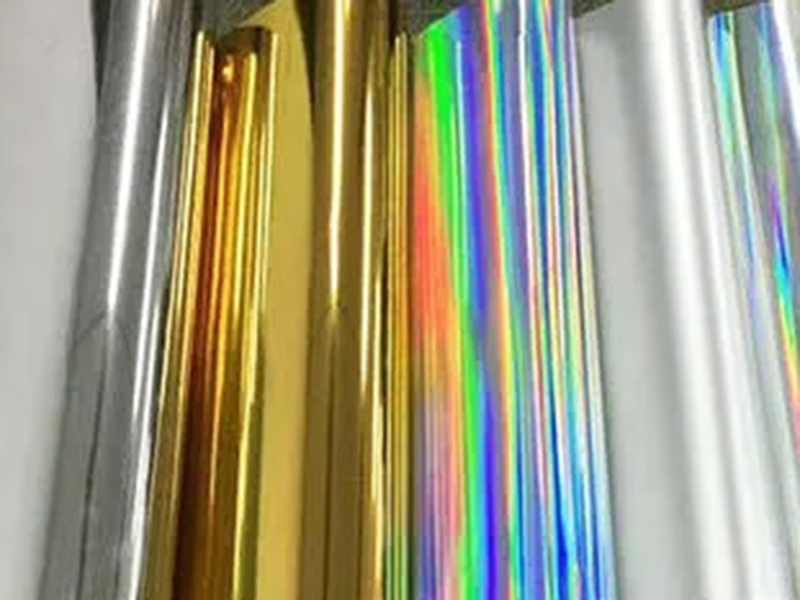

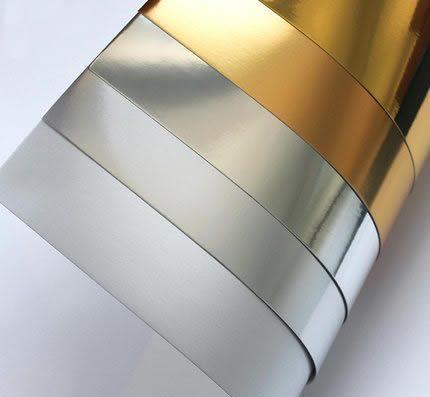

Gold and silver cardboard is a special kind of paper.

It is divided into two types: bright gold cardboard and dumb gold cardboard, bright silver cardboard and dumb silver cardboard; it has very high gloss, bright colors, full layers, and the surface beam has the effect of laser paper. The packaging box made of it has the characteristics of waterproof, corrosion resistance and wear resistance.

Gold cardboard, silver cardboard, and aluminum foil are non-absorbent papers. They are made by pasting aluminum foil on the surface of the cardboard. The non-absorbent nature of the aluminum foil directly affects the dry form of the ink layer.

Precautions for gold and silver cardboard design:

The surface of gold and silver cardboard has high brightness and strong reflectivity. When designing the layout according to the material characteristics, pay attention to highlighting the unique metallic luster of gold and silver cardboard and laser paper that cannot be displayed in spectral colors, and appropriately reveal the metallic color of the surface to express the artistic beauty of the packaging.

Due to the high surface brightness of gold and silver cardboard, a small amount of overprinting is easy to be noticed by the naked eye. Therefore, it is necessary to avoid fine overprinting between multi-color layouts as much as possible. For finely overprinted layouts, consider expanding the margins of light-colored overprint pages by about 0.2mm to avoid obvious whiteness due to overprinting errors.

When planning gold and silver cardboard with solid lines, lines, text, and pictures, avoid using too subtle bold and subtle negative lines, so as not to simply display a paste and affect the printing quality of the product. The best text, lines, borders, and logos should be overprinted on the background color and planned to be dark to make them stand out.

Precautions for printing gold and silver paper cards:

1 Printing ink.

We usually use UV ink for printing. UV inks are mainly used on paper-based absorbent substrates. They have a wider printing water supply range and on-machine safety, giving printed matter better flexibility and higher transparency. It is very suitable for printing on laser gold and silver cardboard.

2 Take anti-sticky measures.

The nature of the gold and silver card aluminum foil paper determines the characteristic that the ink layer cannot dry quickly. Another feature of gold and silver cardboard aluminum foil paper is that it has high smoothness and poor absorption. The printed matter is very prone to stickiness after printing. Once this happens, the smoother and smoother ink layer will instantly become fragmented or incomplete when printed, which will seriously affect the visual effect of the product, or even become a waste product.

3 The temperature of the printing environment.

The ideal ambient temperature is above 25°C. Printing under such temperature conditions is conducive to the drying of the ink layer and is more convenient to operate. If the natural temperature (such as winter) cannot meet certain requirements, the necessary heating facilities can be used.

Post time: Apr-14-2021